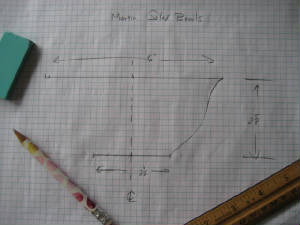

For this set of bowls, my customer decided on this design.

From that profile, a cardboard template is made.

At the woodpile, the walnut logs are first cut along the grain

using a chainsaw.

Each half is cut shorter. Then a disk is screwed to the half

log

to act as a sawing template at the bandsaw.

The blank is cut round at the bandsaw (not pictured here).

Then, using a screw chuck (shown above), the rough blank is mounted

on the lathe.

Here the piece has been turned true on the lathe,

and a tenon is formed at the foot, which will be used to hold

the blank in a four-jaw chuck later for hollowing.

The

bowl's rim diameter of 6" is established now too.

Now the outside profile is cut, and I use the cardboard

template as a guide to check my progess.

The outside of the bowl is sanded before the hollowing begins.

When sanding, I run the lathe much slower than when cutting.

This reduces heat build-up and the resultant "heat checking."

Now the bowl is reversed, so that the tenon is grabbed

by the four-jaw chuck and the bowl can be hollowed and sanded.

The bowl, cut to its final thickness and sanded, is set aside for

about a week to dry.

At this thickness, the wood usually does not

crack but will cup as it dries.

It moves unevenly because a single

piece of wood shrinks more across the grain

than it does in its

length (at the end grain). In flat lumber, this cupping

is

considered a defect, but I like it in a bowl. Of course, the cupping,

while interesting at the rim, would also cause the bowl to sit unevenly

if I had removed the tenon and cut the foot before drying. This is why

I cut the foot after the bowl has dried and moved – so it will sit flat.

This is a piece of scrap wood mounted on the screw chuck.

It is used as a jam chuck for turning the foot.

The bowl is mounted over the jam chuck with bubble wrap in between

for protection.

The tailstock is brought up to hold the bowl in

place. Note the tenon is still there.

Here I have cut away the tenon and formed the final foot.

Now the bowls are finished with a gloss alkyd varnish that has

been thinned

50% with mineral spirits to make it easier to wipe

on. Between coats,

I wet sand with 600 grit paper.

This makes the surface very smooth

to the touch and ready for the

next coat.